Aikexin print quality control system at "Gotek" plants

The Aikexin print quality control system has been successfully implemented on the Shinko processing lines at JSC "Gotek North-West" and JSC "Gotek". The system performs automatic monitoring without human intervention using high-speed high-resolution cameras. They detect the smallest printing defects, shading deviation and color offset ensuring the highest product quality and printing accuracy.

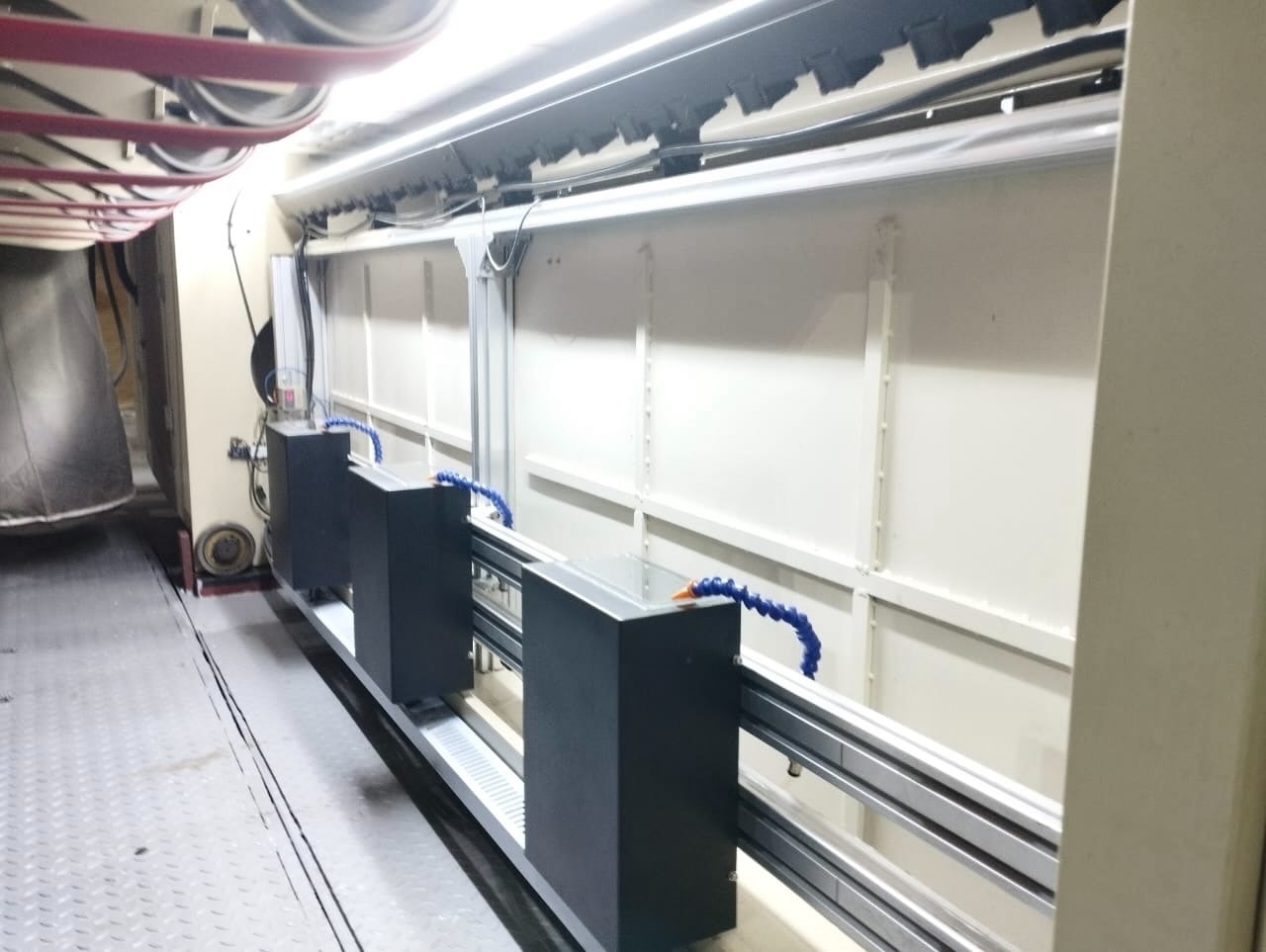

The option is easily integrated into Shinko production lines using movable cameras that cover a specified design/print area on each product. Aikexin is controlled by a separate computer with two monitors for operational quality control.

This technology allows the "Gotek" plants to provide the highest standard of product quality and solve the most complex printing problems arising during the printing process on corrugated cardboard packaging solutions.

The optional Aikexin system has become a key element of the Shinko lines at "Gotek" plants. Thanks to this system productivity and production efficiency is increased.

The supply of Shinko Machine equipment and the Aikexin system was carried out by "Corrugated Technologies" LLC.