Gotek-Print: upgrading the technological equipment base

Today we are creating not just packaging, but an extended product that includes a packaging solution, designed and tailored to the needs of a particular customer, and the associated services. And probably the first important link in this chain is the reliability of technological equipment performance, on which the productivity, on time and quality indicators of the manufactured products are based.

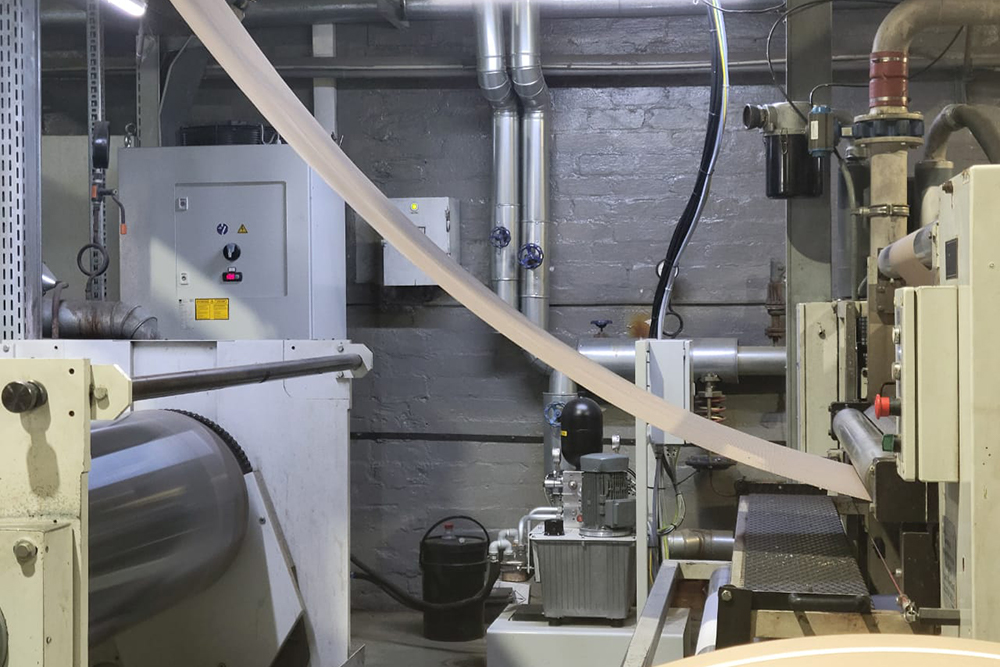

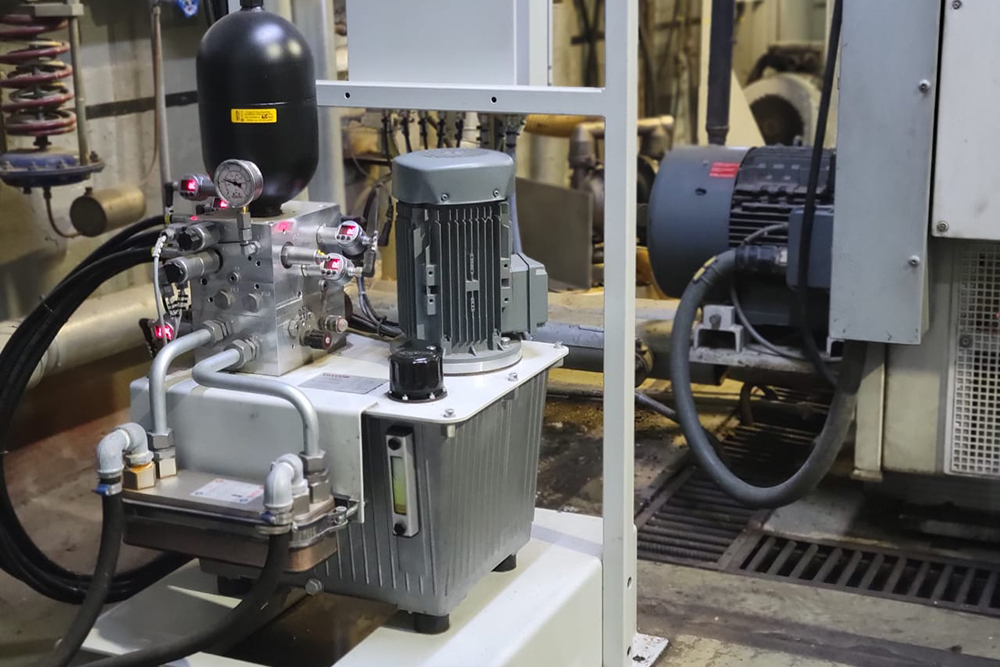

his May Gotek-Print completed the first stage of a large-scale modernization project of one of the key units in the company technological pool - the Asitrade laminating line.

Gotek-Print continues to occupy the leading position in Russia with a share of 36% in the segment of manufacture of packaging from corrugated board with offset printing. And we take the fulfilment of our obligations to customers as a paramount objective. That is why stable operation of the line is vital, and even short-term downtime is unacceptable.

Last fall we decided to carry out a large-scale modernization of the entire line together with the machinery manufacturer BOBST CIS.

Modernization will be implemented in several stages. We have already finished first stage: installed new oil station, replaced obsolete electronics, installed Baumüller latest generation motors and drives, modern controller Simatic Step 7 and the latest hydraulic station HYDAC. Also, remote support program Helpline Plus was installed, which will enable remote equipment fault diagnostics.

All works were performed by Gotek-Print and BOBST CIS experts. This joint project allowed our employees, in addition to many other things, to significantly update and enhance their knowledge of this equipment and its functionality.

In the next stages, we are planning to carry out a radical renovation of the wet part, including installation of splicers and spreaders, and also systematical updates for worn-out parts of the line", - commented Boris Gerasimuk, Director of Gotek-Print.