Packaging solutions for pharmaceutical and health products

Packaging always performs a set of functions, even though it seems simple. And this is an example of just one solution.

Our task is to select and balance the functionality for your needs. And we are ready to solve it together with you. You can contact one of the company's sales services (see the map) to do this.

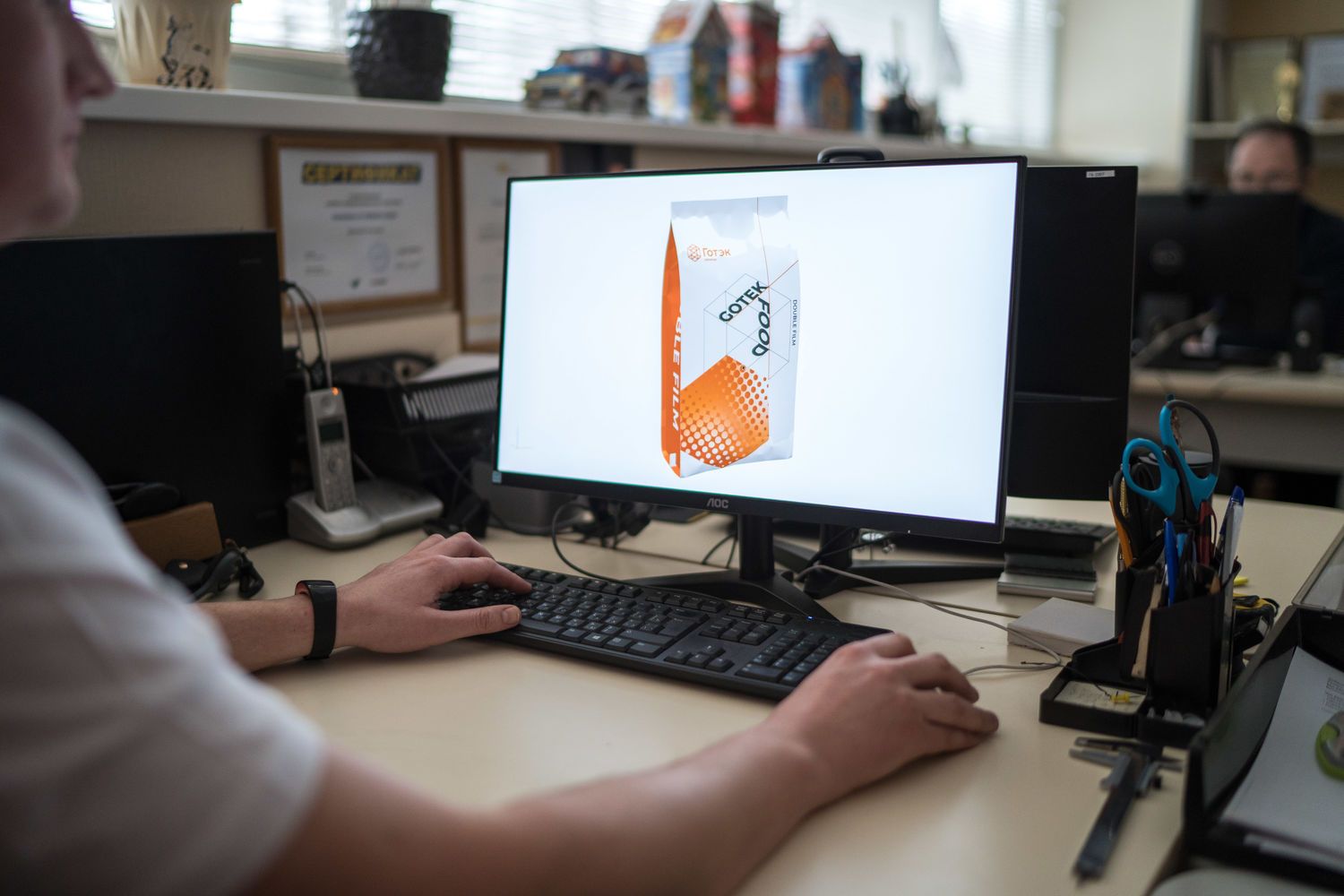

How do we do it?

Up to 5 days from conception to prototype!

If we have access to the necessary information for design and

depending on the complexity of the task, the developing

process will take from 1 to 5 days.

How to get a prototype in 1 day?

The best way is to organize a work session with your employees. It is based on the careful needs study of each packaging user and their transformation into the packaging solution functionality. This approach makes it possible to get the optimal necessary packaging layout within one working day.

75% of participants in the sessions held at the 4D Lab R&D

centers admitted that the result exceeded their initial

expectations.

The R&D centers where we conduct the sessions united under

the brand 4D Lab, and are available at every company site.

They are equipped with everything you need to research a

concept, design and pre-test a prototype packaging solution.

An online format is available to save your time or when

travel is restricted.

You can get more information from the sales staff listed on the map.

You can learn more about our work methods at a special website dedicated to our packaging approach.

With our help you can look into the store space and imagine how the new solution will work on the shelf

The virtual store allows you to simulate a 3D layout of your new product in a realistic sales floor, including the use of SRPs, displays and other promotional solutions.

You will be able to compare your new products with real

competitors on the store shelf, assess the visual and

communicative components of the package, and quickly make

changes to the functional or graphic design, if

necessary.

You can make changes to the graphic design in real time!

You can do this in the a collaborative work sessions format.

Store Visualizer capabilities allow you to achieve a high

level of realism, reproducing the smallest details:

different lighting options, shadows in the shelves back,

features of materials and printing effects. Instant

rendering allows you to see the changes in just a few

minutes!

You are looking at the shelf "through the eyes of the customer"

You can place packaged goods anywhere in the sales floor, simulating different display options (on the shelf, in floor and suspended structures). They can be moved, picked up, rotated and put in place, thus simulating the real "customer experience".

You can export images in high resolution or create a video to

demonstrate your colleagues.

You can get more information from the sales staff listed on the map.

You can learn more about our work methods at a special website dedicated to our packaging approach.

How to test the developed solution reliability in the "tightest" logistics cycle in just 5 days?

Gotek organized the first laboratory in Russia certified by the International Safe Transit Association (ISTA) as part of the 4D Lab complex.

Special facilities enable tests to be carried out on an individual package or packaging system:

- exposed to temperature and moisture;

- reproduce identical to the real vibrations to which the package will be affected during transportation;

- check resistance to impact and compress.

The laboratory tests allow:

- reduce the time for packaging design, to be sure of the new product launch timely;

- select the optimal material capacity of the packaging system without the risk of product loss;

- ensure optimal logistics costs;

- improve the environmental component of packaging;

- increase customer satisfaction and brand loyalty.

As a test shipping result the only thing you can do is record that something went wrong. The cause can be determined only in the laboratory. In contrast to real tests, lab tests:

- reproducible (the same test can be repeated under absolutely identical conditions);

- comparable (two identical tests results can be compared, but two different transportation results can't);

- prompt (most tests are conducted within one day,

packaging acclimatization within 72 hours is an

exception).

You can get more information from the sales staff listed on the map.

You can learn more about our work methods at a special website dedicated to our packaging approach.